company-profile-module $!{companyProfile}

Liquid argon air temperature Ambient Air Heated vaporizer

Popular

Popular in

-

1 - 99 Sets

$21,021.00

-

>=100 Sets

$19,223.00

- Model Number:

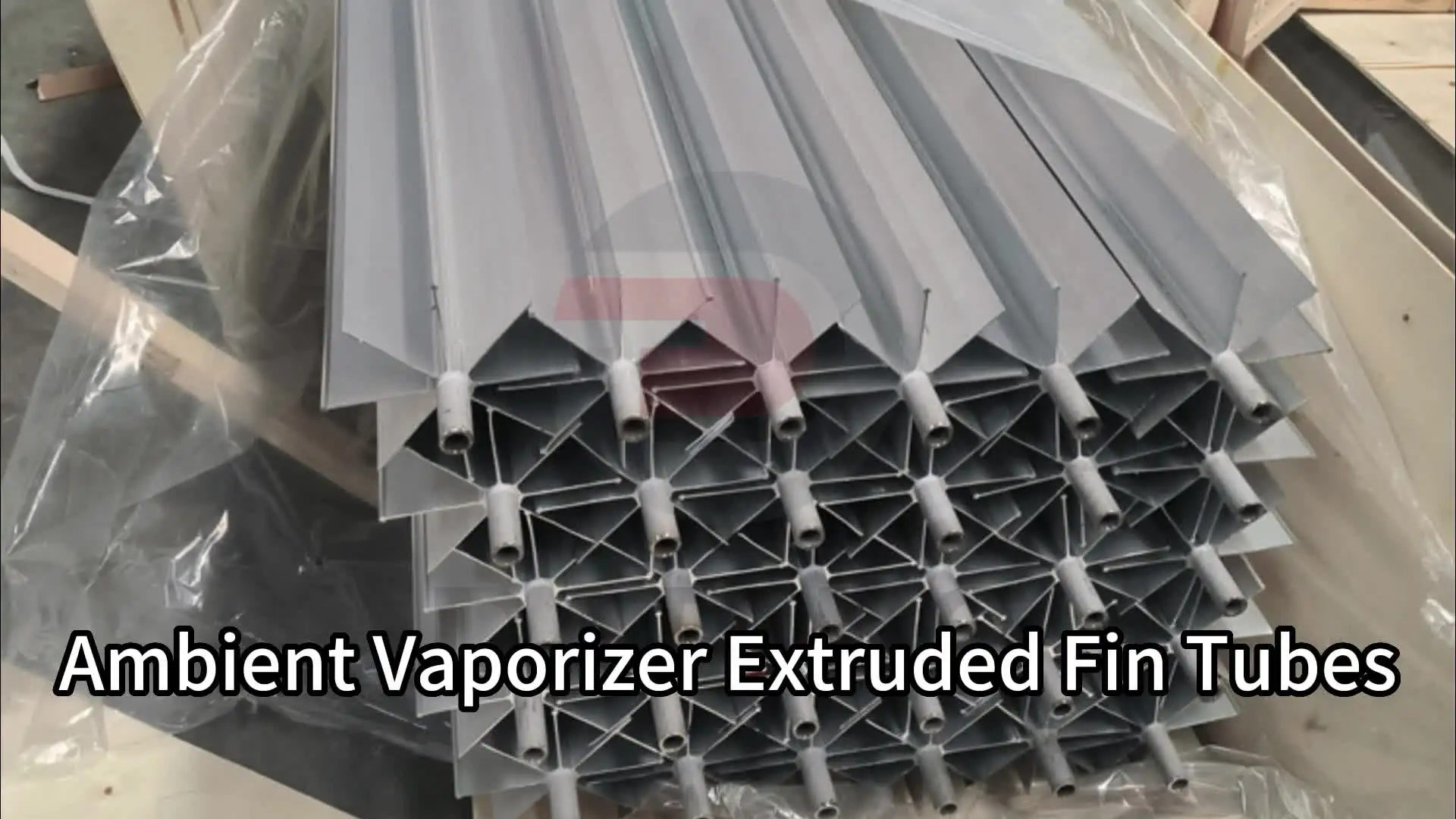

- star shaped aluminum fin

- Power:

- /

- Inventory Status:

-

In Stock

- Samples:

-

star shaped aluminum fin , /

- Lead time:

-

Quantity(Sets) 1 - 1 >1 Lead time (days) 15 Negotiable

- Customization

-

Customized logo (Min. Order: 1 Sets)Customized packaging (Min. Order: 1 Sets)

More

Graphic customization (Min. Order: 1 Sets) Less

Product details

Company profile

Overview

Essential details

- Voltage:

-

220v/380v/440v

- Structure:

-

Tube Heat Exchanger

- Warranty:

-

1 Year

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Warranty of core components:

-

1 Year

- Core Components:

-

fin tube

- Condition:

-

New

- Place of Origin:

-

Hebei, China

- Brand Name:

-

OEM

- Liquid Flow Rate:

-

Max

- Maximum Working Pressure:

-

1000bar

- Weight:

-

6300 KG

- Dimension(L*W*H):

-

Customized, 11800mm*2980mm*2980mm

- Working Temperature Range:

-

/

- Key Selling Points:

-

Long Service Life

- Product name:

-

Ambient Air Vaporizer

- Use:

-

LO2,LN2,LAr,LNG,LCO2,LC2H4

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Description:

-

5000Nm3/h LNG Ambient vaporizer

- Working Pressure:

-

0.8-80Mpa

- Capacity:

-

50-16,000Nm3/h

- Application Industries:

-

LNG Service

- Material:

-

Aluminum

- Medium:

-

LO2,LN2,LAr,LNG,LCO2,LC2H4,LPG

Packaging & delivery

- Lead time :

-

Quantity(Sets) 1 - 1 >1 Lead time (days) 15

Online Customization

Products Description

Ambient Air Vaporizer

When falling from 3-meter-high spot, hot water will be cooled down. This is because heat exchange occurs between the water and the air. Similarly, ambient air vaporizer makes use of the large temperature differences between the cryogenic liquid and the ambient air. The transfer efficiency is improved by increased fin numbers and expanded contact area with the air. So this cryogenic vaporizer achieves a rapid and complete vaporization.

Type: Vertical, three-row, five-stage, water-cooled cylinders without oil lubrication, water cooling, piston type

Exhaust volume: 180 m 3 / h (inhalation conditions)

Medium: dry oxygen

Suction temperature:<40°C

Maximum working pressure: 16.17 MPa (165kgf/cm2)

Piston stroke: 180mm

Cooling water consumption: 6T/hr

Compressor speed: 232r.pm

Motor speed: 960 rpm

Motor power: 55kw

Power supply conditions: 380V (three phase) 50Hz

When falling from 3-meter-high spot, hot water will be cooled down. This is because heat exchange occurs between the water and the air. Similarly, ambient air vaporizer makes use of the large temperature differences between the cryogenic liquid and the ambient air. The transfer efficiency is improved by increased fin numbers and expanded contact area with the air. So this cryogenic vaporizer achieves a rapid and complete vaporization.

Type: Vertical, three-row, five-stage, water-cooled cylinders without oil lubrication, water cooling, piston type

Exhaust volume: 180 m 3 / h (inhalation conditions)

Medium: dry oxygen

Suction temperature:<40°C

Maximum working pressure: 16.17 MPa (165kgf/cm2)

Piston stroke: 180mm

Cooling water consumption: 6T/hr

Compressor speed: 232r.pm

Motor speed: 960 rpm

Motor power: 55kw

Power supply conditions: 380V (three phase) 50Hz

Ambient Air Vaporizer Specification

Model | Maximum evaporation (Nm3/h) | Maximum working pressure (Mpa) | Body material | Empty weight (kg) |

QQ-50/25 | 50 | 2.45 | 5A02 | 100 |

QQ-100/25 | 100 | 2.45 | 5A02 | 185 |

QQ-150/25 | 150 | 2.45 | 5A02 | 245 |

QQ-180/25 | 180 | 2.45 | 5A02 | 330 |

QQ-200/25 | 200 | 2.45 | 5A02 | 350 |

QQ-350/25 | 350 | 2.45 | 5A02 | 560 |

QQ-500/25 | 500 | 2.45 | 5A02 | 610 |

QQ-1200/25 | 1200 | 2.45 | 5A02 | 2100 |

QQ-2000/25 | 2000 | 2.45 | 5A02 | 3220 |

QQ-4000/25 | 4000 | 2.45 | 5A02 | 5500 |

The Advantages of Ambient Air Vaporizer:

-1).No energy consumption, no pollution, environmental protection;

-2).It uses special aluminium material to exchange heat and high efficiency and lightweight design to keep a long service life;the special design of Φ160,Φ200 of large finned aluminium tube heat exchanger to increase the defrosting speed;The unique design of "bridge" type connection, it increases the load capacity and integral stiffness, and it effectively eliminates all parts of thermal stress generated by working;Aluminium heat exchanger tube has surface oxidation treatment.

-3).Optimization of process design, the Pressure drop is reduced to the minimum, no drift phenomenon, ensures the flow control in a safe range.

Ambient air heated vaporizer utilizes air natural convection to heat the cryogenic liquid(LOX,LIN,LAr,LCO2,LNG,LC2H4,LPG,etc.)in the heat exchange tubes,making them totally evaporate into gases ,it is a kind of high efficient energy-saving heat tranmission equipment. Its major advantage lies in:

★ No power consuming,no pollution,green and environmental protective

★ Easy installing,convenient maintaining

★ Patented efficient aluminum material for heat exchanging,high effective,light weight design,and endurable

★ Professional design,removing ice cream easy,continuous long operation

★ The bridge style connecting component sees pretty,and also can eliminate the stress that has been generated because of the

expanding by heating and the shrinking by colding.

★The design of optimizing the flowing has lowed the stress into the lowest lever,and eliminated the deflection phenomenon,and then it can control the speed of flowing within safe range

★ Advanced and complex technique of high-pressing pipe makes the under pressing pipe has a sufficient

contact with the heat exchanging pipe,and ensures the efficiency of heat exchanging

★ All the vaporizer's manufacturing and cleaning are according to the standard of oxygen service which is much safer for usage

★ Design conditions:temperature -20ºC,relative humidity 70%,continuous use time not less than eight hours.

★ Remark:elements to influence the vaporization volume:cycle of working,environmental temperature humidity,height above the sea level,wind power,illumination,the using press nearby buildings,etc.

-1).No energy consumption, no pollution, environmental protection;

-2).It uses special aluminium material to exchange heat and high efficiency and lightweight design to keep a long service life;the special design of Φ160,Φ200 of large finned aluminium tube heat exchanger to increase the defrosting speed;The unique design of "bridge" type connection, it increases the load capacity and integral stiffness, and it effectively eliminates all parts of thermal stress generated by working;Aluminium heat exchanger tube has surface oxidation treatment.

-3).Optimization of process design, the Pressure drop is reduced to the minimum, no drift phenomenon, ensures the flow control in a safe range.

Ambient air heated vaporizer utilizes air natural convection to heat the cryogenic liquid(LOX,LIN,LAr,LCO2,LNG,LC2H4,LPG,etc.)in the heat exchange tubes,making them totally evaporate into gases ,it is a kind of high efficient energy-saving heat tranmission equipment. Its major advantage lies in:

★ No power consuming,no pollution,green and environmental protective

★ Easy installing,convenient maintaining

★ Patented efficient aluminum material for heat exchanging,high effective,light weight design,and endurable

★ Professional design,removing ice cream easy,continuous long operation

★ The bridge style connecting component sees pretty,and also can eliminate the stress that has been generated because of the

expanding by heating and the shrinking by colding.

★The design of optimizing the flowing has lowed the stress into the lowest lever,and eliminated the deflection phenomenon,and then it can control the speed of flowing within safe range

★ Advanced and complex technique of high-pressing pipe makes the under pressing pipe has a sufficient

contact with the heat exchanging pipe,and ensures the efficiency of heat exchanging

★ All the vaporizer's manufacturing and cleaning are according to the standard of oxygen service which is much safer for usage

★ Design conditions:temperature -20ºC,relative humidity 70%,continuous use time not less than eight hours.

★ Remark:elements to influence the vaporization volume:cycle of working,environmental temperature humidity,height above the sea level,wind power,illumination,the using press nearby buildings,etc.

Medium | LO2/ LN2/ LAr/ LNG/ LCO2/ LC2H4/ LPG/ LNH3/ LH2/etc. |

Working Pressure | 0.2~40MPa |

Capacity | 50~10000Nm3/h |

Standards | GB/ ASME/ PED/ CE/ CCS/ CNNC/ CASC |

Remark | Please choose the combination units if larger flow demands. |

Inspection&Packing

Factory Photos

Customers Visit Our Factory

Why Choose Us

Contact Us

Sunny Yang

Mob:+86 15690122018

Whatsapp:+86 15690122018

Wechat:15690122018

Skype:info@datangpipe.com

Email:info@datangpipe.com

You May Like

Not exactly what you want? 1 request, multiple quotations Get Quotations Now >>

You May Like

For more detailed information including pricing, customization, and shipping:

Contact supplier

Call Us

Call Us

Call Us

Call Us

Trading Company

|

≤1h

Response Time

The average amount of time supplier took to respond to every buyer’s first message over the past 30 days.

|

|

| On-time delivery rate |